This Vampire is a very simple model to put together so I figured it would be a good first test for me on Finecast. If any of you reading this blog do not know what finecast is, you either are not a table-top war-gamer or you have been living under a rock for a LONG time. Put simply, Finecast was touted as the "end-all and be-all" of model medium. Better than plastic and better than metals, finecast was supposed to be the choice material for models, but...it didn't quite work out that way, now did it?

See, when finecast was released it had a lot of problems and was quickly labeled as "failcast" by those not to happy with Games Workshop for making the change over. So here is my first finecast model.

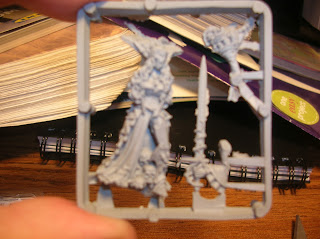

As you can see from these two pictures, this model has a lot of flash on it, particularly on the sword and on the very top of the vampire. I also inspected a lot of other fincast models spanning different ranges and they all seemed to have a lot of flash on them. this seems to be a common thing in finecast.

Now, flash isn't a big deal, it comes off easy and you usually don't know it was ever there after the model is assembled and painted. The bigger problem is if there are air bubbles and miscasts in the model. This has been a problem since the Fincase release. I inspected the model and could not find any miscasts or air bubbles. the sword was even straight. Win for me.

I was able to get the flash removed from the model very easily. I normally hate scraping mold lines and flash off of a model, but finecast is much softer and the flash came off so easily. not a problem

It even came off of the sword very easily and no damage to the sword its self. very easy to work with and very quick.

And here it is fully assembled. it was also very easy to glue together, much easier than plastic or metal. in conclusion, I loved working with finecast. I think it is very good medium when you get a good model with no defects. The problem is that people have been getting defective casts and that pisses them off.

No comments:

Post a Comment